Cambiar idioma :

Mobile power socket supplies container ships at the Port of Hamburg with shore power quickly and flexibly

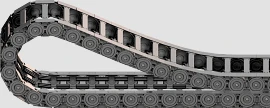

Three movable energy chains on the quay ensure the precise supply of energy for ships.

At Container Terminal Hamburg (CTH), three mobile shore power connections have been installed on the quays to ensure a flexible, fast and safe power connection for container ships. Over lengths of 300, 150 and 110 metres, the shore power connection at the CTH is precisely aligned with the ship's berth. Roller energy chains, which guide the heavy cables safely and compactly, help to move the mobile "sockets". The system not only reduces operating costs and increases safety. It also makes the shore power concept much more attractive as an alternative to operating environmentally harmful diesel generators to supply power to the moored ships.

Products used

Flexible power supply

Energy supply at the quay

Energy supply on the panel

Motor cables

Strain relief

Sensors for chain/cable

Contacto

¿Preguntas o información sobre productos? Por favor, póngase en contacto con:

igus® México.+52 728 2843185Correo

Servicio al cliente

Servicio al Cliente:

Teléfono: De lunes a viernes, de 8:00 a 20:00

Chat en vivo: 24 horas