Cambiar idioma :

About 10 times longer service life with iglide® J3

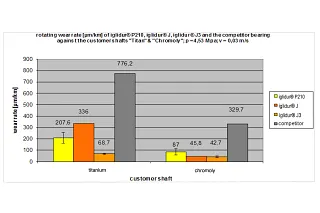

To find the ideal iglide® material for a manufacturer of high-end mountain bike pedals, we received different shafts of titanium and chrome molybdenum steel, as well as bearings of a competitor. On this basis we tested our iglide® plain bearings in the iglide® laboratory.

The trials were executed under the following test parameters:

Shafts: Titanium, chromoloy steel

Load: 657 psi

Slide speed: 0.098 ft/s

Result:

The iglide® J3 bearings have the lowest wear rate on both shaft materials (36.6 μm/km to 73.3 μm/km). These were the best test scores in the test. In contrast, the plain bearings of the competitor material wear out on both shaft materials at rates of 329.7 μm/km to 776.2 μm/km.

More Information

Now you may order the winner of the test:

The new endurance runner: up to three times more wear resistant than iglide® J up to 1,450 psi

iglide® J3

iglide® J3 - material data

iglide® J3 - the fast- and slow-motion specialist

iglide® J3 - material dataApplication examples

Do you wish to test a custom application?

We will gladly test your specific application as well. Simply use the contact form!

dry-tech® test lab

Contacto

¿Preguntas o información sobre productos? Por favor, póngase en contacto con:

Servicio al cliente

Servicio al Cliente:

Teléfono: De lunes a viernes, de 8:00 a 20:00

Chat en vivo: 24 horas