Cambiar idioma :

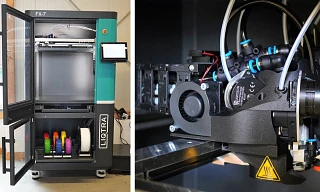

Lubrication-free bearing technology and compact energy supply for multi-nozzle 3D printers

High temperatures prevail in 3D printers, and the use of multi-nozzle technology in particular requires precise movements of the individual nozzles. The moving components used must fulfil these requirements and also be lubrication-free so as not to contaminate the filaments. Liqtra GmbH, an expert for additive manufacturing, therefore relies on drive technology, conveyor rollers and energy chains from igus. They help to ensure that an economical and sustainable 3D printing process with increased productivity can be achieved.

Application Overview

- What was needed: Conveyor rollers for the filaments, lead screws with nut and stepper motor for the z-axis, energy chains to guide the power and data cables

- Requirements: Lubrication-free, temperature resistance at 80°C, long service life, compact size to fit into the limited installation space

- Industry: 3D printer construction, medical technology

- Success for the customer:that the power supply and data transport function reliably.

Relevant Products

Contacto

¿Preguntas o información sobre productos? Por favor, póngase en contacto con:

igus® México.+52 728 2843185Correo

Servicio al cliente

Servicio al Cliente:

Teléfono: De lunes a viernes, de 8:00 a 20:00

Chat en vivo: 24 horas