Cambiar idioma :

Plain Bearings for Root Ball Transplanters

iglide® Application

Application Overview

The spades are pushed slowly into the soil. The polymer plain bearings are able to deal with dirt, moisture, etc.

Root ball transplanters are indispensable tools for tree nurseries and for garden and landscaping businesses. They gently transplant trees of any size. Hydraulic cylinders are used to slowly, but with immense force, push the spades into the soil, cleanly severing the roots. Maintenance-free polymer plain bearings demonstrate their strengths in all areas that involve rotating and swiveling movements. They are maintenance-free, work under dry-running conditions and are particularly insensitive to dust and dirt.

For nearly ten years, the agricultural engineering company has been relying on iglide® G from igus® GmbH, Cologne. The all-rounder bearing is particularly resistant to external influences. More than 650 dimensions are available from stock.

"And we make full use of this spectrum", states the mechanical engineer, Reiner Irsigler. "There is almost no dimension that we do not use in our broad model range. In addition, the price/performance ratio is also spot-on, which of course makes economic sense."

Moisture and soil have no influence of any kind on the functionality of the individual machinery components.

The areas where the spades enter into the soil are also subject to any imaginable abrasive loads. Moisture and a broad temperature spectrum are topics that can also not be ignored. "The tree transplanting campaign that took place in the winter of 2011/2012 in the Stuttgart Schlosspark as part of the new rail station construction was subject to a very tight timeline. In addition, the temperatures were in a deep freeze“, Roland Schlesag recalls an actual episode. "None of the machines we used experienced malfunctions of any kind. “ In addition, the tribo-optimized plain bearings are able to handle any edge load without difficulty, for instance when the spades impact rocks.

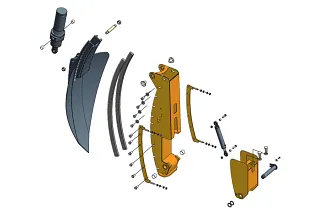

Polymer plain bearings in the various hinges, locks and hydraulic cylinders of the root ball transplanter.

From left: Uwe Sund (igus® GmbH), Roland Schlesag (General Manager at Optimal-Vertrieb Opitz GmbH), Dirk Lanuschni (igus® GmbH), Reiner Irsigler (Mechanical Engineer at Optimal-Vertrieb Opitz GmbH).

The root ball transplanter uses tribo-optimized cylindrical standard plain bearings made from iglide® G materials in a host of available dimensions. These are simply ordered from the catalog. The application spectrum is always the same on all machines, allowing the agricultural engineering firm to rely on standard solutions. "It simply works", comments Dirk Lanuschni, the responsible igus® sales consultant. "The iglide® G material is known as an all rounder. It comprises a broad spectrum of possible applications and is characterized by high wear-resistance and low friction values. “

3D rendition of the guide box: a host of applications for polymer plain bearings.

This also includes another engineering detail that plays an important role and underscores the versatility of polymer plain bearings: "At some point the single-sided load will cause a red brass bushing to wear, which impacts tolerances. The clearance continues to increase until a bolt fails. Even though we used to use hardened bolts, for instance in the hinges, they still failed", the mechanical engineer recalls. "Bolt failures are now a thing of the past. The softer plastic material yields elastically, which completely avoids the notch damage that is the starting point for a failure."

Contacto

¿Preguntas o información sobre productos? Por favor, póngase en contacto con:

igus® México.+52 728 2843185Correo

Servicio al cliente

Servicio al Cliente:

Teléfono: De lunes a viernes, de 8:00 a 20:00

Chat en vivo: 24 horas