Cambiar idioma :

Roller Coaster Switch and Shunting Track Solutions

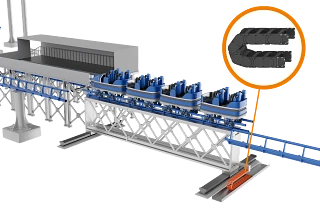

Optimize Amusement Ride Operations with igus® Shunting Track Systems

igus® shunting track systems are designed to provide seamless switching between multiple tracks, ensuring efficient operation and increased ride uptime. Our solutions are ideal for roller coasters and other amusement rides, offering enhanced reliability and low maintenance.

Benefits of igus Shunting Track Systems

- Low Maintenance: Reduced maintenance requirements result in lower operating costs.

- Enhanced Reliability: Durable components ensure consistent performance.

- Smooth Switching: High-precision systems allow for seamless transfer between tracks.

- Extended Lifespan: Robust materials designed to withstand dynamic loads.

- Improved Safety: Minimized risk of malfunctions during track transfers.

- Energy Efficiency: Optimized systems reduce energy usage, improving operational efficiency.

Learn how igus® technology can optimize the performance of Shunting tracks for roller coasters and amusement rides, reducing maintenance and improving reliability.

Key Components of igus® Shunting Track Systems:

Success story: Six Flags roller coaster with maintenance-free bearings

The operator of the amusement park chain Six Flags relies on plain bearings made from the material iglide Z, which has led to a significant cost reduction here. The reason: maintenance work could be completely dispensed with during the season. With the dry-operating plain bearings made of high-performance plastic, there is no need to check the mounts and shafts or to relubricate them. Another plus: the bearings save a lot of weight.

Challenges in Designing Shunting Track Systems

Precision and Alignment: Ensuring the switch tracks align perfectly every time is crucial to avoid derailments or damage.

Mechanical Complexity: Switches and transfer tracks involve complex mechanical systems that must operate reliably under various conditions.

Maintenance Access: These components are often located in hard-to-reach areas, making regular maintenance challenging. Specialized equipment and procedures are required for servicing.

Wear and Tear: Continuous movement and high loads lead to significant wear; using durable components is key to preventing failures.

Safety Systems: Ensuring that safety mechanisms like sensors and locking systems function correctly is vital to prevent accidents.

Operational Downtime: Maintenance or repairs may require taking the ride out of service, leading to potential revenue loss.

FAQ: Common concerns about Roller Coaster Switch Systems

Reliability can be improved by using igus® E4 series energy chains and chainflex® cables, which are designed to handle the dynamic loads and constant movement of roller coaster switches. These components reduce wear and provide consistent performance, minimizing failures.

Regular inspection and maintenance are essential. Using advanced lubrication systems, vibration dampening technologies, and igus® predictive maintenance tools can help identify wear early and reduce the need for frequent servicing.

Inspection frequency depends on ride usage, but it's recommended to perform regular checks weekly. With igus® maintenance-free e-chains and real-time monitoring, you can reduce the need for constant manual inspections.

Implementing igus® heavy-duty E4.1 series energy chains, advanced lubrication systems, and high-strength wear-resistant materials helps extend component life. These solutions reduce friction and impact forces, minimizing wear in high-traffic areas.

Explore Amusement Ride Manufacturer Solutions by igus

Contacto

¿Preguntas o información sobre productos? Por favor, póngase en contacto con:

igus® México.+52 728 2843185Correo

Servicio al cliente

Servicio al Cliente:

Teléfono: De lunes a viernes, de 8:00 a 20:00

Chat en vivo: 24 horas